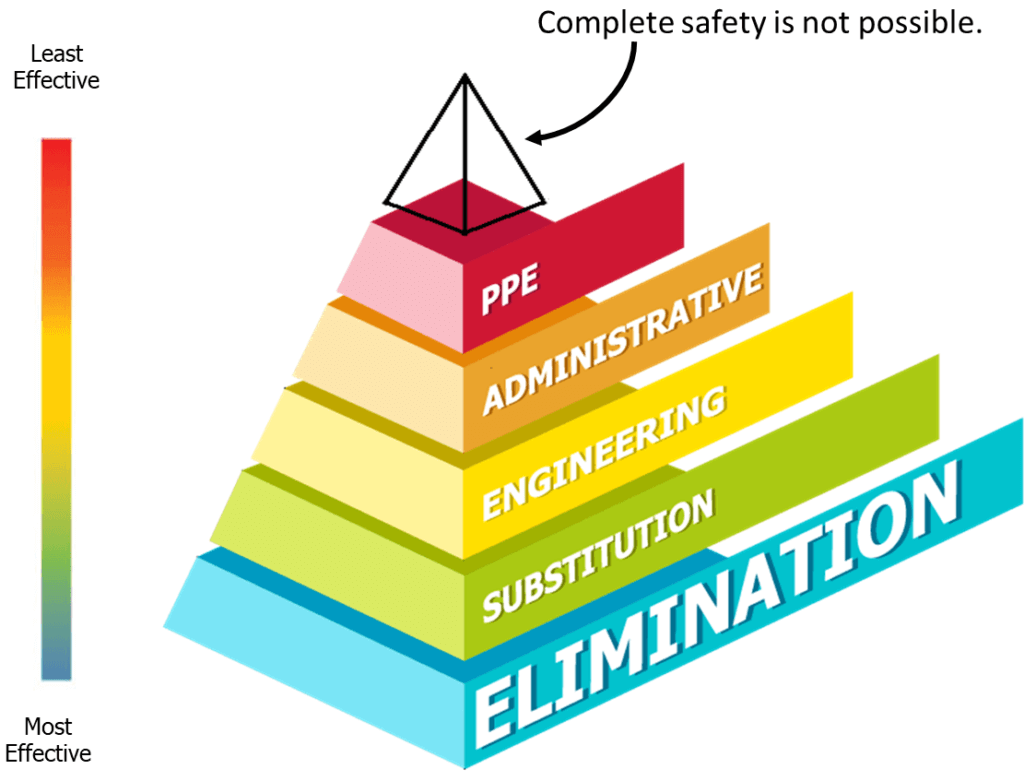

Identifying and mitigating exposures to occupational hazards before work begins is the objective of all safety and health professionals. The National Institute for Occupational Safety and Health (NIOSH) offers a basic outline to improve workplace safety through its interpretation of the Hierarchy of Controls.

The hierarchy starts with the controls perceived to be most effective moving to those considered least effective. As defined by NIOSH, it flows as follows:

- Elimination – Physically remove the hazard

- Substitution – Replace the hazard

Elimination and substitution of hazards can be the foundation of workplace safety. By preventing workers from accessing the hazard without requiring active effort, solutions that eliminate or substitute a hazard can be the most effective. Point guarding locations such as rotating bearings, covering the gap between a motor and pump, and preventing access to rotating shafts are among the simplest and most cost-effective ways to increase worker safety.

- Engineering controls – Isolate people from the hazard

- Administrative controls – Change the way people work

Engineering controls are favored over administrative and personal protective equipment (PPE) for controlling existing worker exposures in the workplace because they are designed to remove the hazard at the source, before it comes in contact with the worker.

- Personal protective equipment – Protect the worker with PPE

PPE programs may be relatively inexpensive to establish but over the long term, can be very costly to sustain and may not be adequate for some applications. This method of protecting workers has proven to be less effective than other measures as it requires active effort by the affected workers.

Human interaction, physical failure of system components and other unanticipated factors make complete safety unattainable. The B11.0 Safety of Machinery and B11.19 Risk Reduction standards recognize that there is no such thing as absolute safety, just ways of making production processes safer, and offers guidance on how to make them as safe as possible.